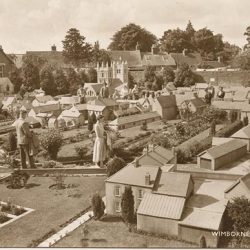

Double trouble? Charlotte Collins visits Wimborne’s miniature doppelgänger to learn how 3D printing has opened up a world of possibilities in preserving the long-lasting history of the Model Town for future generations.

Its magnificent one-tenth scale models continue to draw in visitors from all around the world. When you walk through Wimborne Model Town, you trace the footsteps of history. Guests are given a unique opportunity to not only be giants for a day, but to see what Wimborne used to be like in the 1950s.

For over 60 years, volunteers have worked tirelessly to preserve and maintain the model for the generations that proceed them. The winter season is an especially busy time for the Model Town. Closed to the general public, the volunteers repair and restore the models, and most of the work is done by hand.

“Once we finish for autumn half term we change completely,” says Greg Hoar, the general manager of Wimborne Model Town. “The little buildings get stripped out of all their fixtures and fittings. All their windows come out, all the shop fronts come out – they are all washed and catalogued as to the state that they’re in, repainted, refinished and any repairs done to them as necessary. And that takes us quite some time, from the beginning of November through to a week before we open.”

But recently, the historic Model Town has begun exploring the possibilities that the latest digital technologies can offer. When the Model Town moved from its original site to its current location in 1991, the 22 ton concrete model Minster was cut into pieces with a large angle grinder. 25 years down the line, the model has begun looking a bit tired.

“Quite a lot of works gone on to the Minster this year. It’s been the focus of an awful lot of activity in this closed season,” says Hoar. “It’s an ongoing programme but we’ve been refreshing the windows using 3D printing – which is terribly advanced for somewhere like the Model Town – but we’ve also combined the digital technology to take images of stained glass windows that exist in the real Minster and bring those across to the mini one in 1/10th scale.”

The mini-Minster’s little quarterjack bell-ringer has also been restored to full working order. When the Model Town’s steam-driven quarterjack ground to a halt, the decision was made to go digital. “We’ve now got a little Raspberry Pi computer that’ll now run all of that, and the bells are now going to ring on the quarter and hourly chimes but two minutes after the real things, so you can hear them, then hear us!”

The experiments with 3D printing for the Model Town have proved promising. “If the technologies and the materials are right, and a lot of this are under test – it has all sorts of possibilities for replacing little bits of buildings and interiors.

“The possibilities are huge to somewhere like us.”